Case Study: 8 weeks to capture $2 million

Overview

In today’s manufacturing environment, efficiency is the difference between profits and losses. This case study highlights how a food production client was able to achieve a substantial production increase on their most profitable production line. Through targeted data analysis, process improvement, and effective communication strategies, together we delivered measurable results - an annual margin improvement of $2,000,000 within just eight weeks.

The Challenge

Before our engagement, the client faced a recurring issue: their most profitable production line consistently failed to meet planned production levels. Despite management's efforts, the root causes of inefficiencies remained unclear.

Key Issues:

Lack of actionable data: Existing processes did not provide the granularity needed to diagnose production bottlenecks effectively.

Delayed start-up times: The line was delayed by an average of 52 minutes each morning, resulting in lost production time and idling of eight employees.

Ineffective management directives: Verbal instructions to “start on time” lacked actionable steps, leading to frustration without results.

Our Approach

Step 1: Data and KPI Development

We began by identifying the client’s current data capabilities and enhancing them to capture actionable insights. Key process improvements included:

Hourly case count tracking: To measure actual vs. theoretical production.

Downtime reason codes: Employees recorded the cause and duration of any stoppages, providing a clear dataset for analysis.

This new approach revealed that delayed start-up times were the single largest cause of downtime, accounting for an average of 52 minutes lost per day.

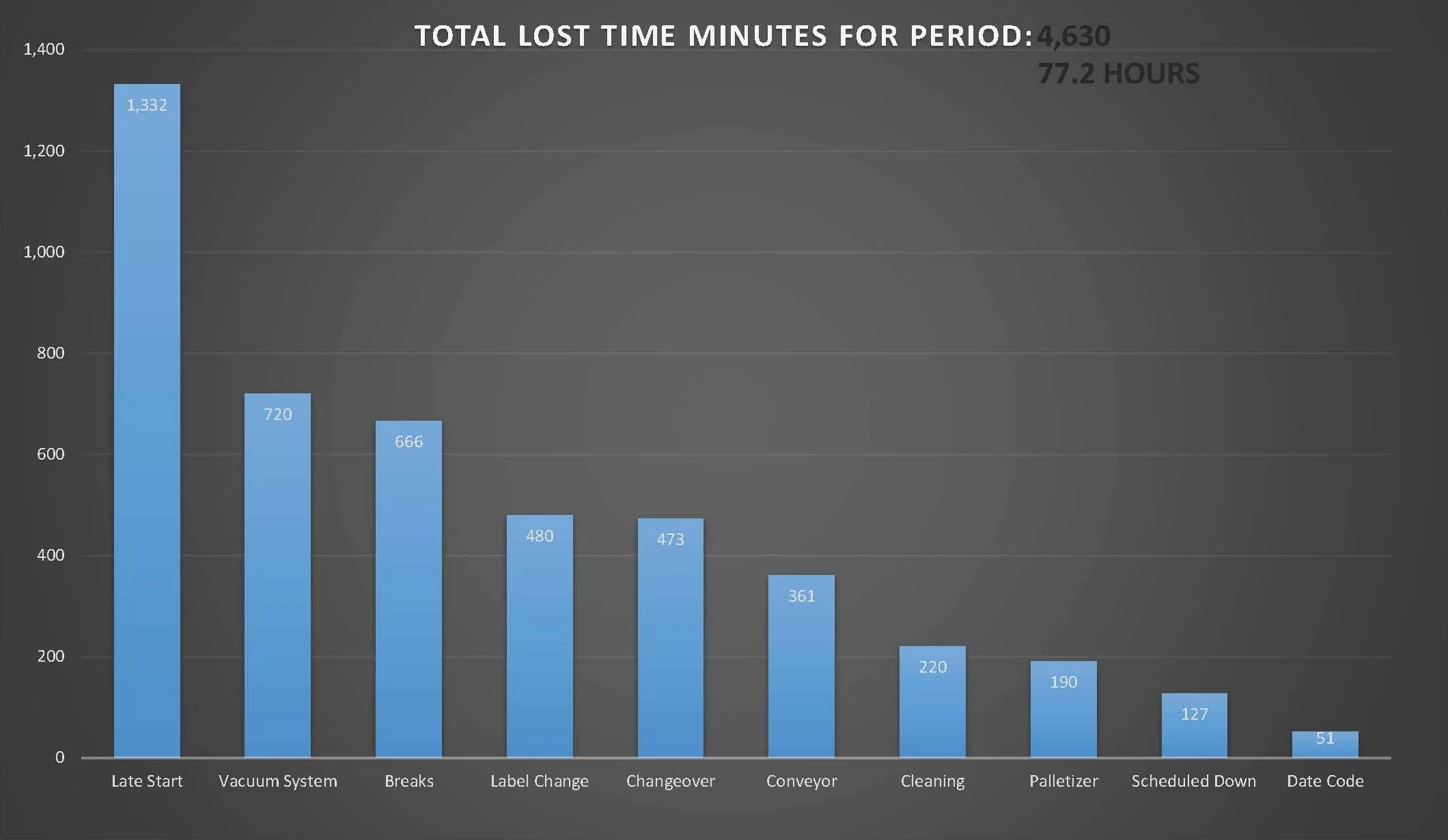

The Daily Schedule Control (DSC) used on the floor to generate amount of downtime minutes, reason codes, and production impact.

A pareto analysis of several DSCs over several days showed the majority of lost production time was due to late starts.

Step 2: Root Cause Analysis

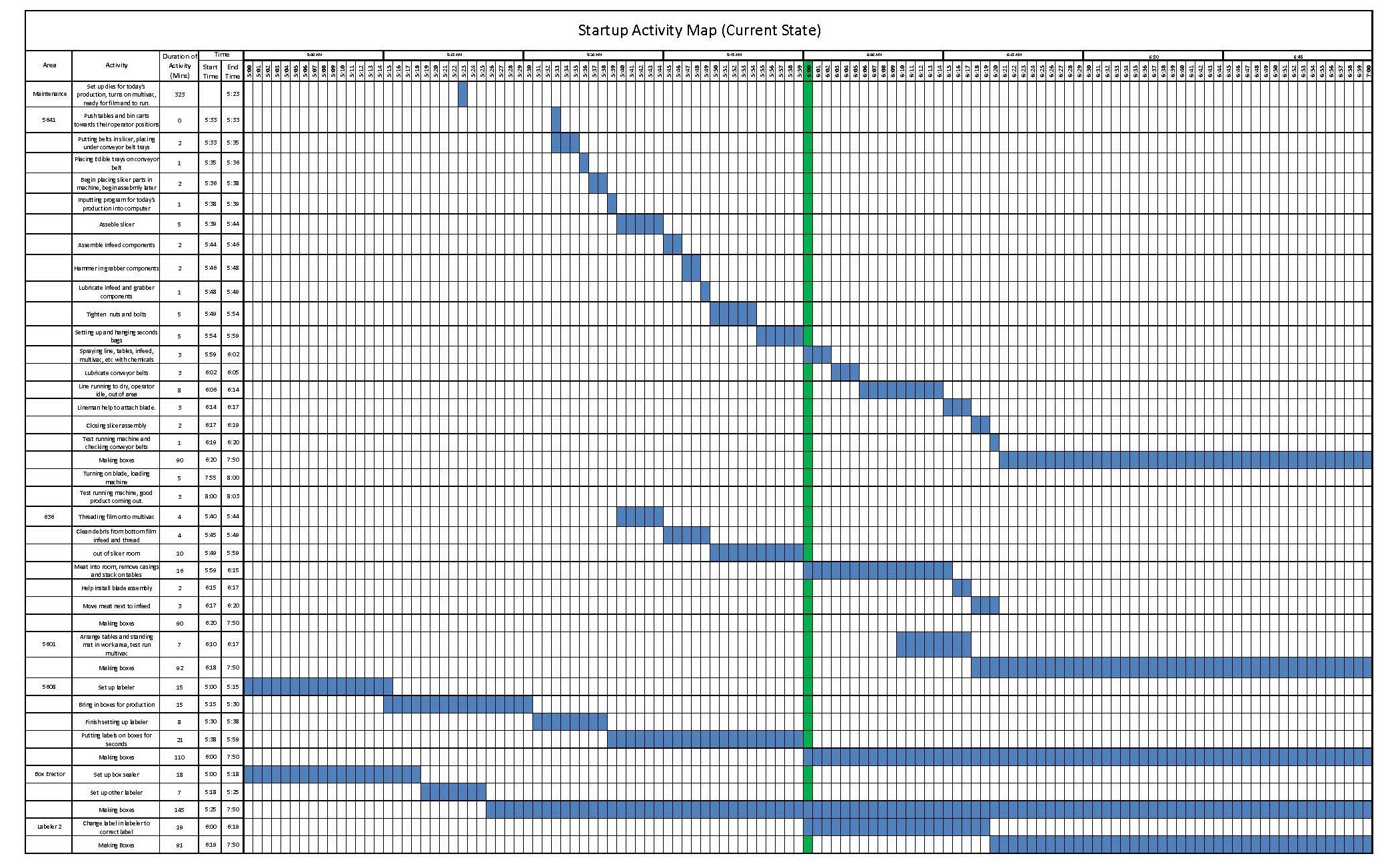

To address start-up inefficiencies, we conducted a version of Single Minute Exchange of Die (SMED) analysis. This minute-by-minute evaluation highlighted critical issues:

Disorganized availability of tools and equipment.

Inefficient sequencing of tasks, with all work performed sequentially rather than in parallel.

Cleaning, setup, and troubleshooting activities consuming excessive time.

Step 3: Targeted Recommendations

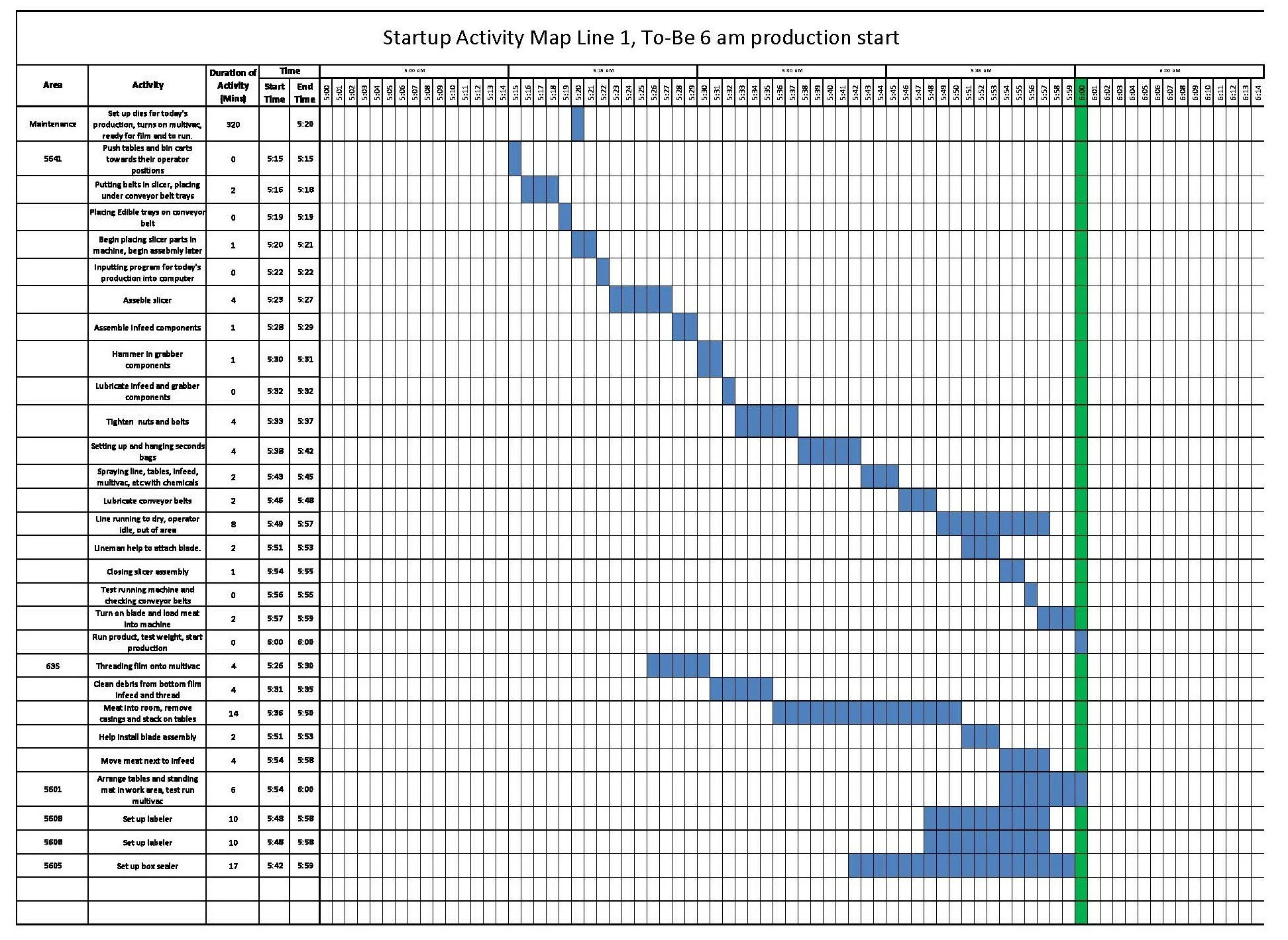

Based on the findings, we implemented several process and organizational changes:

Kitting process: Ensured tools and parts were pre-assembled and readily available, reducing search time.

Parallel tasking: Introduced a second employee during start-up to perform tasks simultaneously.

Published timelines: Created a detailed minute-by-minute start-up procedure, enabling employees and supervisors to monitor progress in real time.

Step 4: Coaching for Collaboration

Recognizing the importance of the human element, we coached managers and supervisors on effective communication. By framing process improvements as a collaborative effort rather than a critique of employee performance, we turned the workforce into active contributors to change.

Results

Our approach yielded exceptional results:

Start-up delays reduced from 52 minutes to under 3 minutes per day.

49 additional minutes of daily production time gained.

$2,000,000 in annualized margin improvement on the highest-margin product.

These outcomes were achieved in just eight weeks!

Insights and Key Takeaways

Data-Driven Decision-Making: Granular KPIs and downtime tracking enabled precise identification of bottlenecks.

Process Optimization: Tools like SMED analysis provided actionable insights to streamline operations.

The Human Factor: Effective communication fostered a culture of collaboration, transforming employees into problem-solvers.

Rapid ROI: A focused and disciplined approach can drive significant results in a short time frame.

The client’s president summed up the impact best:

“If I had known we could be this much more efficient, I would have started this project years ago.”